Dr. Ing. Simon Wurzbacher & Dr. Ing. Julian Schild & B. Eng. Max Müller

Priamus Fill Control simplifies cascade injection molding in family molds

"A Family in Sync"

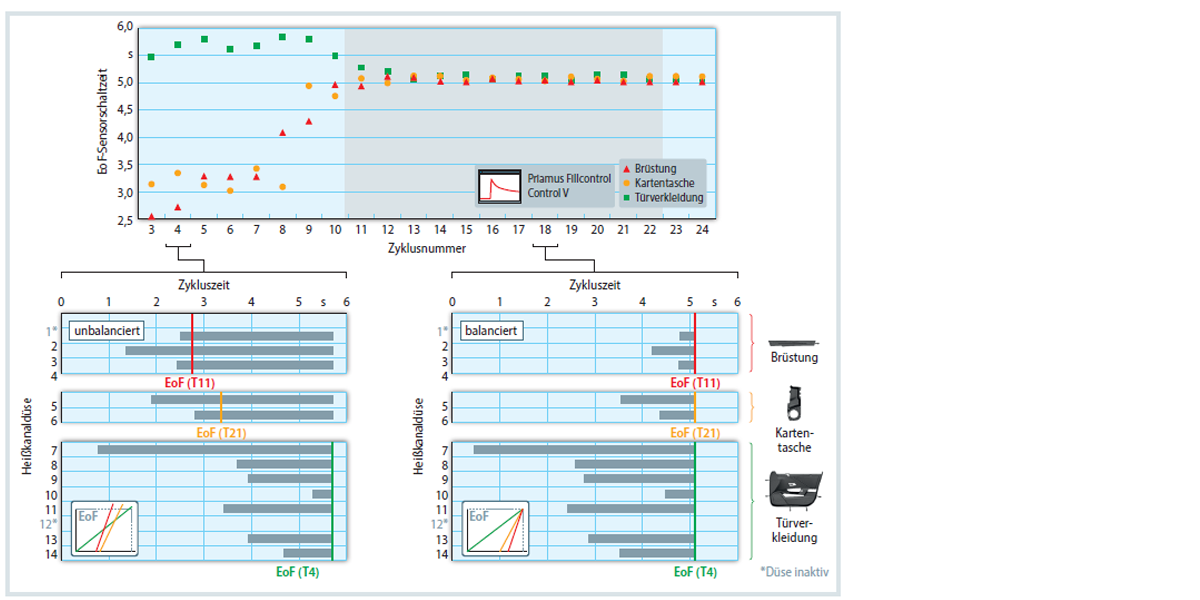

When injection molding specialists talk about balancing, they are referring to the synchronous reaching of the end of the melt flow in the cavities. It would consequently be better to refer to this as “synchronizing.” This synchronization of the end of the melt flow is influenced by several parameters: the molding compound, the injection molding machine, the tool, and the hot runner. With family molds, in particular, with multiple connections of the parts, synchronizing becomes an even greater challenge. We show an alternative to complex manual cascade settings in a realistic test set-up.

Manual cascade settings and adjustments to process interferences

Setting up a complex cascade application from scratch is time-consuming and requires a lot of experience. During process development, the setter encounters a conflict between even mold filling (preventing flow marks, flow lines, and air inclusions) and a homogeneous holding pressure effect (preventing local sink marks). At the same time, they must move the unavoidable flow lines into acceptable areas of the part. To achieve the quality of the required part, this conflict is influenced by adapting the cascade switching times of the valve gate nozzle depending on the screw position. These switching times, however, are in turn dependent on the injection speed and the division of the volumetric flow to the respective valve gate nozzles.

For family molds that produce an assembly ‒ for example, a door trim panel ‒ the cascade settings become even more complex due to the different part properties, especially the part volume and wall thickness. The described division of the volumetric injection flow between the open valve gate nozzles means that a change in the switching time on one part will influence the filling of the other part. In addition to controlling the quality of several parts, the setter is confronted with the challenge of synchronizing the end of the flow path of all parts to avoid overpacking.