Control Your Process

Get the most out of your hot runner system with Gammaflux Temperature Controllers and Priamus Process Monitoring and Control Systems.

Meet all challenges of injection molding for consistent part quality. Examples include eliminating visible weld lines on large parts, creating the best surface quality in the painting process, optimizing the production of functional areas that are subject to high loads, mastering quality and batch variations and much more!

Control your Process.

Get the most out of your hot runner system with Gammaflux Temperature Controllers and Priamus Process Monitoring and Control systems.

Meet all challenges of injection molding for a consistent part quality:

- Visible weld lines on large parts such as the dashboard

- Poor surface quality in the painting process

- Quality fluctuations in multi-component parts or material overmolding

- Batch variations in the material

- High-quality surfaces meet functional areas that are sometimes exposed to very high stress

- ...And much more!

Gammaflux Hot Runner Temperature Controllers

Gammaflux Hot Runner Temperature Controllers

Even when our customers have identified the perfect process, an injection molding machine is a living, ever-changing force with variables constantly challenging that process. Gammaflux takes the stress out of managing those variables.

Gammaflux compares the actual temperature to the setpoint and then calculates the exact amount of power required to maintain that setpoint through a unique PID2 algorithm.

/Process%20Control/synventive-process-control-systems-gammaflux-hot-runner-temperature-conteoller-image.jpg)

Even when our customers have identified the perfect process, an injection molding machine is a living, ever-changing force with variables constantly threatening that process. Gammaflux takes the stress of managing those variables away.

Gammaflux constantly compares the actual temperature to the setpoint and then calculates, through a unique PIDD algorithm, the exact amount of power required to maintain that setpoint.

- Triangulated Control Technology

- LEC Series

- G24

- G 24 SVGC

- G24 + HPU

Achieving Better Temperature Control

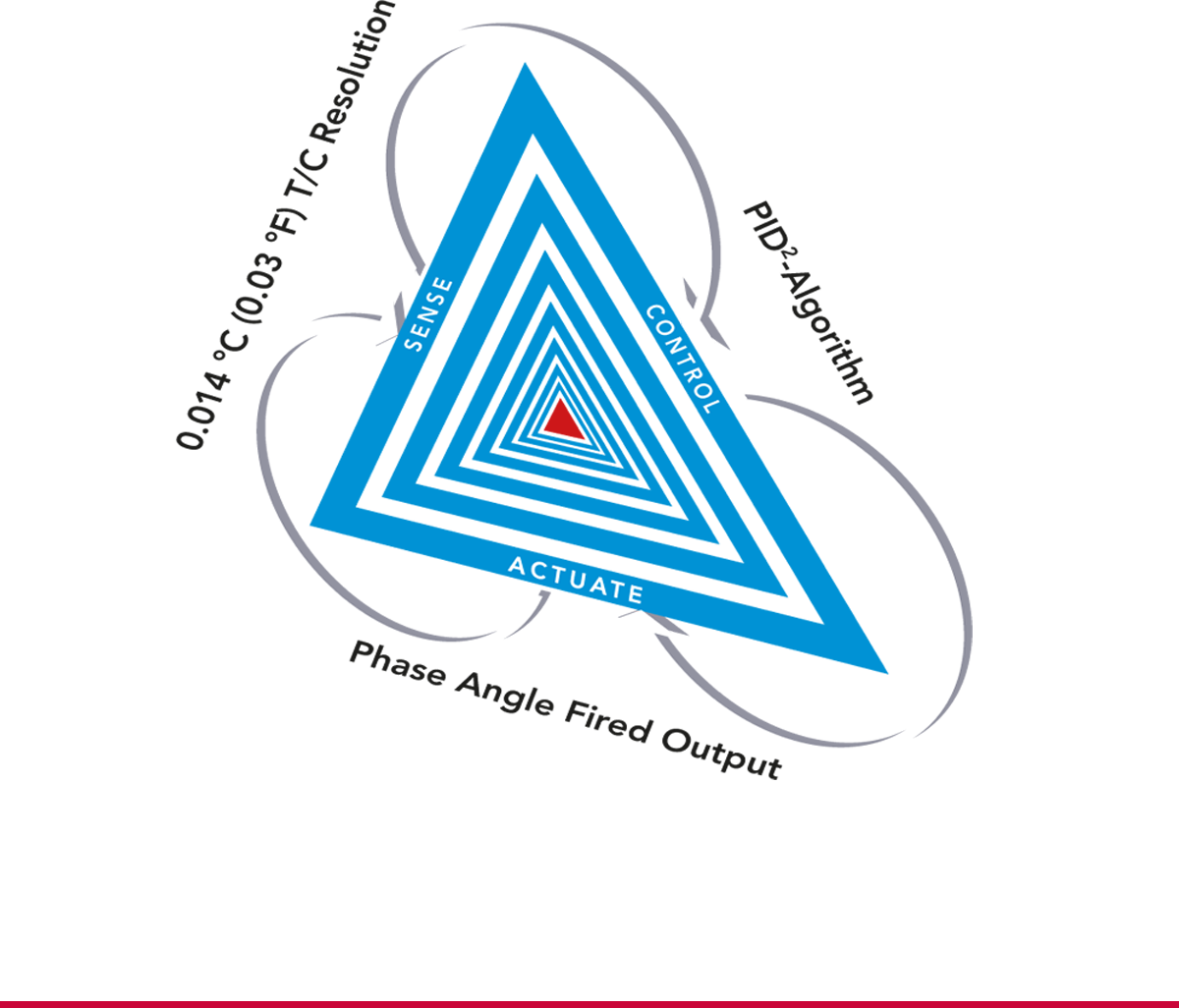

C O N T R O L The proprietary, self-optimizing Gammaflux PID2 control algorithm adjusts if the actual temperature deviates 0.03 ºF (0.014 ºC) from the setpoint. The second derivative (PID2) monitors the rate of change in the actual temperature. As a result, the output to the heater is regulated in advance of the typical proportional band to limit or eliminate overshoot and undershoot.

A C T U A T E Using phase angle control (0.1% resolution, 1,000 steps), the Gammaflux controller ensures smooth and precise power delivery to each heater.

Controls for up to 24 Zones

Designed for smaller hot runner system applications, the LEC can be supplied with 2, 6 and 12 zone enclosures. A network module allows daisy-chaining of two 6- or 12-zone enclosures for control of up to 24 zones. The modular design of the LEC allows simple control card removal, addition or replacement.

Control up to 192 Zones in One Enclosure

With daisy chain cable up to 384 zones in 2 enclosures.

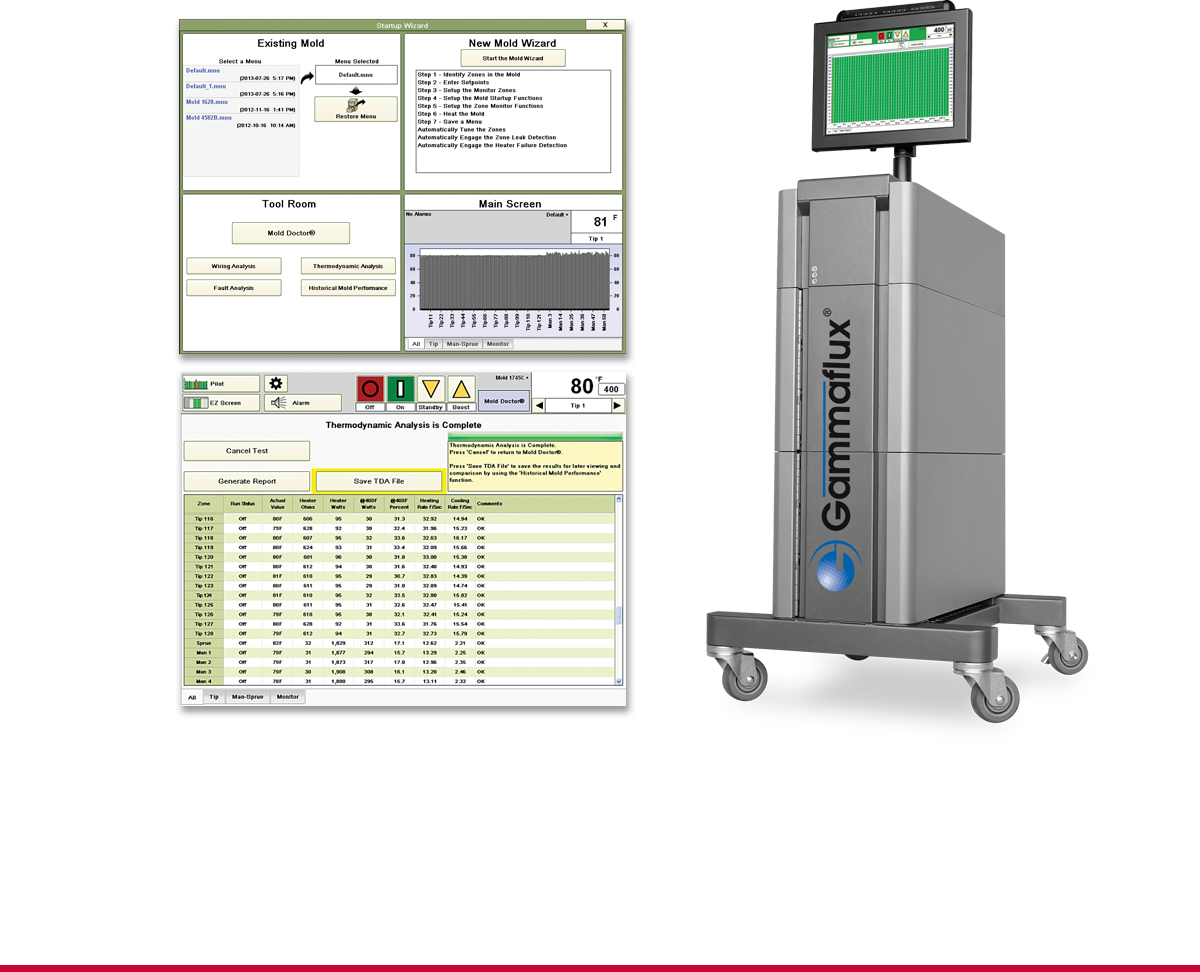

Focused on the plastics industry, Gammaflux is an expert in process optimization. The G24 is everything you would expect in a next generation control system:

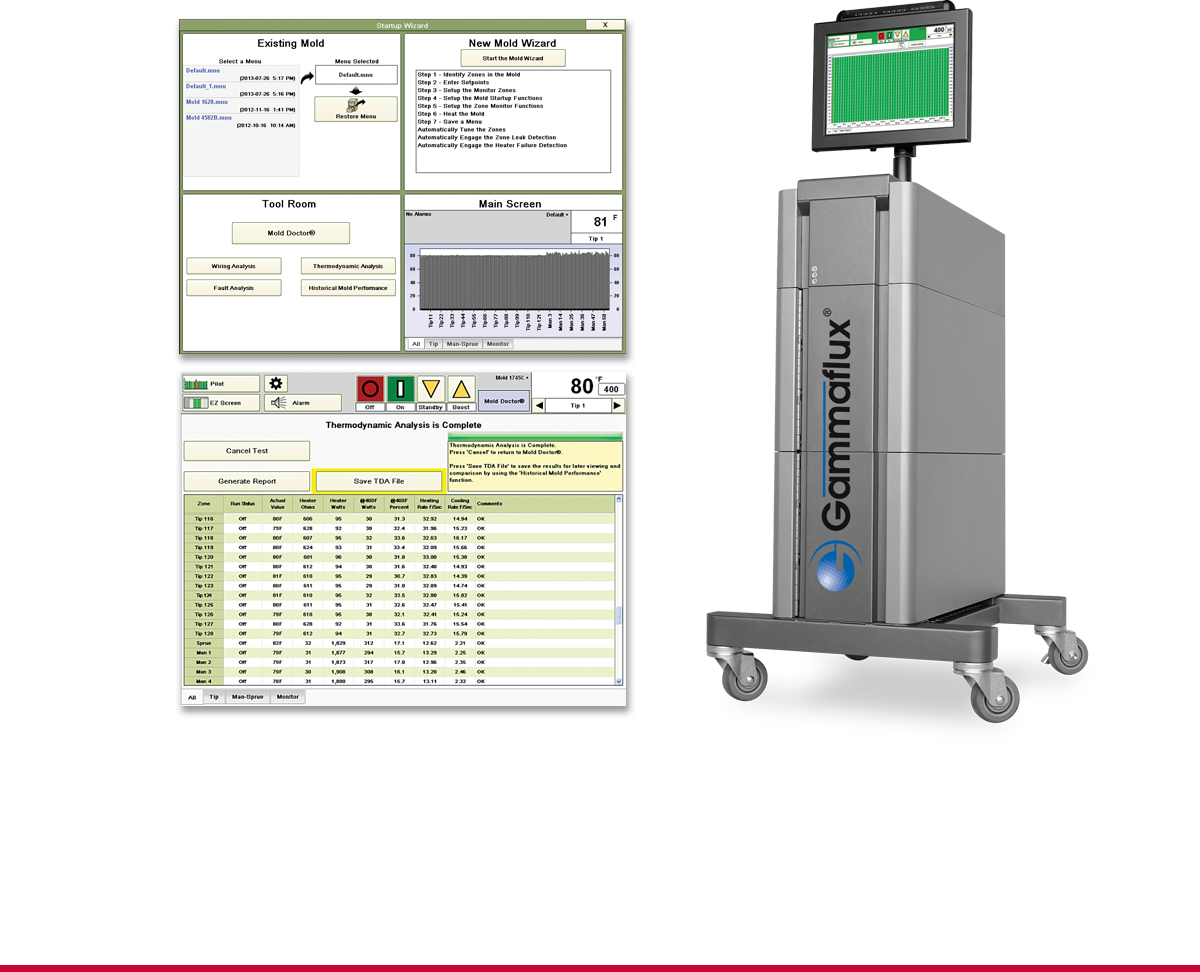

MOLD WIZARD Your Assistant who guides you easily through the intsallation process. The Wizard makes everyone a controller configuration expert.

EARLY LEAK DETECTION for faster detection of a leak in your hot runner. Early detection of leaks not only save money, but also speed up the restart of the mold.

MOLD DOCTOR is an automated mold troubleshooting feature that detects elusive problems that occur suddenly.

Sequential Valve Gate Control (SVGC)

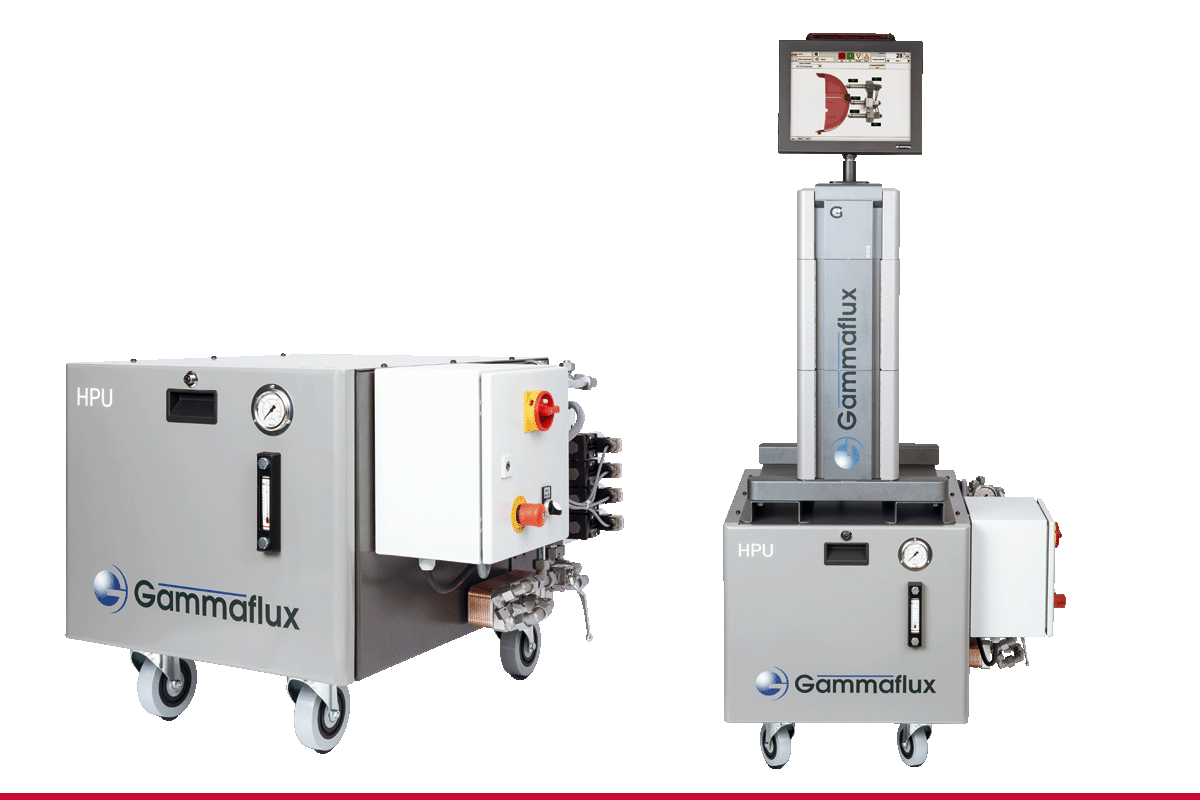

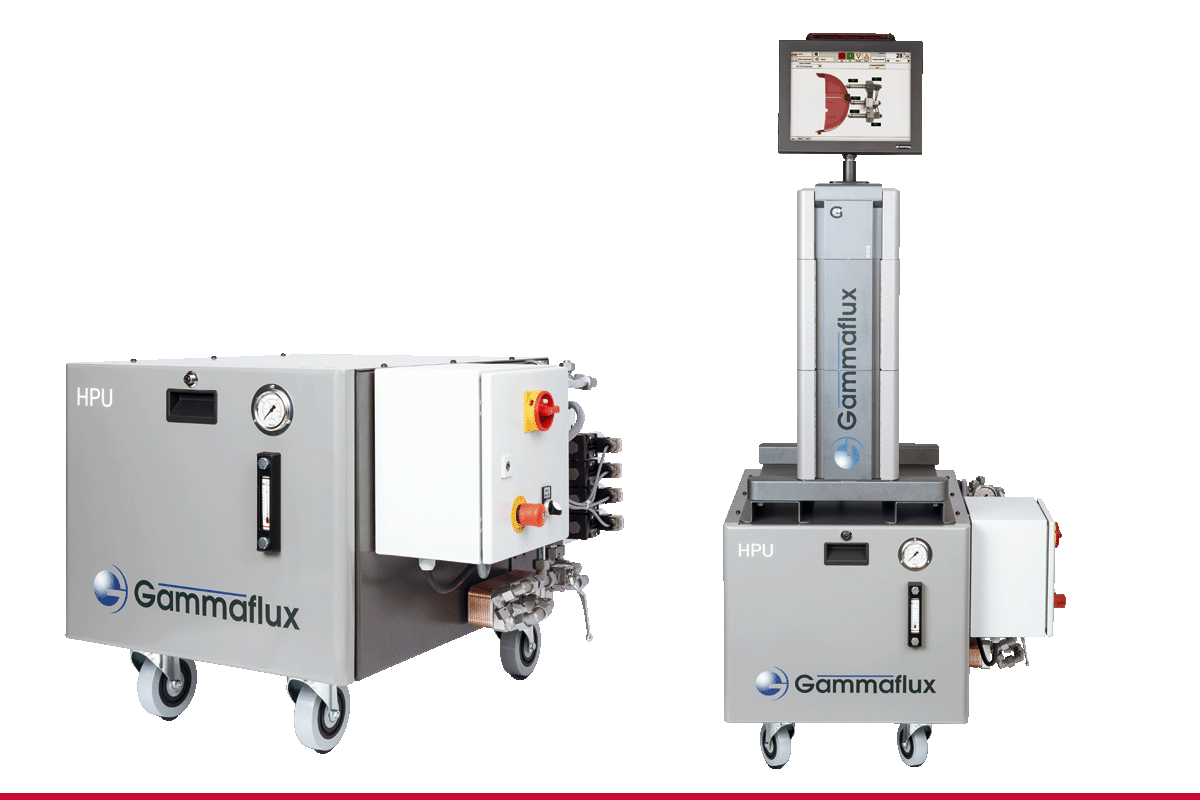

Hydraulic Power Unit HPU

- LEC Series

- G24

- G 24 SVGC

- G24 + HPU

Controls for up to 24 Zones

Designed for smaller hot runner system applications, the LEC can be supplied with 2, 6 and 12 zone enclosures. A network module allows daisy-chaining of two 6- or 12-zone enclosures for control of up to 24 zones. The modular design of the LEC allows simple control card removal, addition or replacement.

Control up to 192 Zones in One Enclosure

With daisy chain cable up to 384 zones in 2 enclosures.

Focused on the plastics industry, Gammaflux is an expert in process optimization. The G24 is everything you would expect in a next generation control system:

MOLD WIZARD Your Assistant who guides you easily through the intsallation process. The Wizard makes everyone a controller configuration expert.

EARLY LEAK DETECTION for faster detection of a leak in your hot runner. Early detection of leaks not only save money, but also speed up the restart of the mold.

MOLD DOCTOR is an automated mold troubleshooting feature that detects elusive problems that occur suddenly.

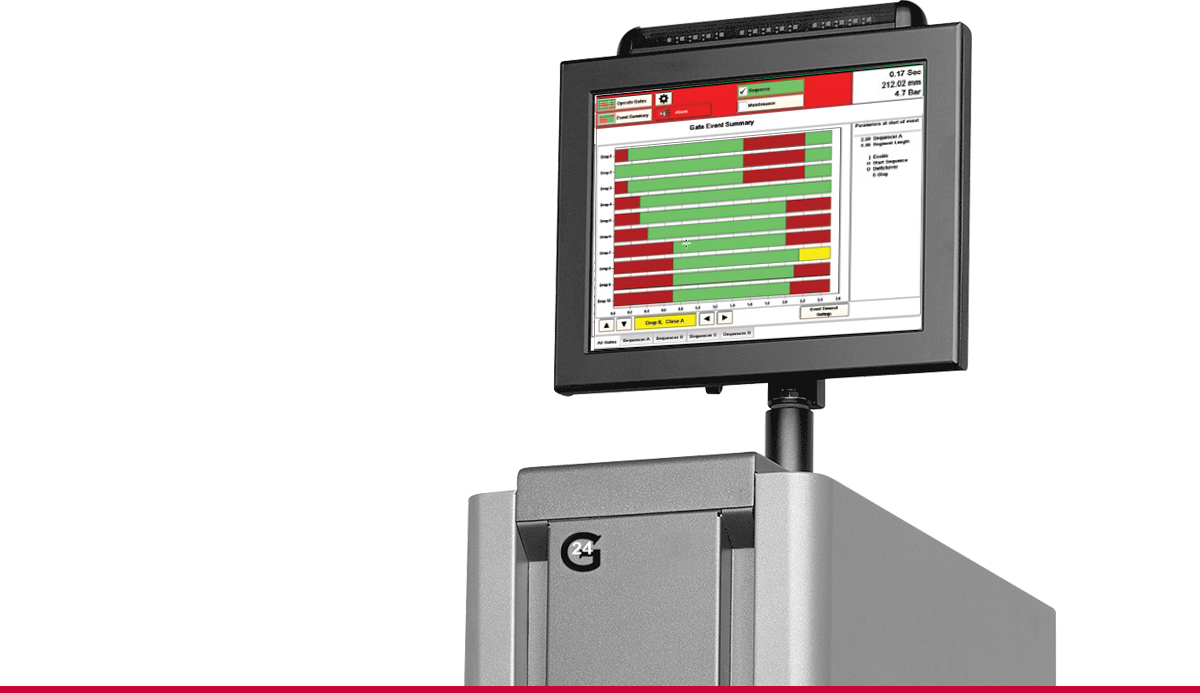

Sequential Valve Gate Control (SVGC)

Hydraulic Power Unit HPU

Priamus Closed Loop Process Control

Identify ‒ Regulate ‒ Eliminate

By combining real process parameters recorded directly in the mold by sensors for cavity pressure and cavity temperature, Priamus gains a holistic picture of the process and can, for example, monitor the melt flow in the mold.

Depending on the melt flow, Priamus automatically corrects the settings of the hot runner nozzles so that weld lines in large-area components can be controlled, moved, and held in position in a targeted manner to produce perfect components.

- FILLCONTROL

- FILLCONTROL Switch

- FILLCONTROL H

- FILLCONTROL V

Fill Control Architecture

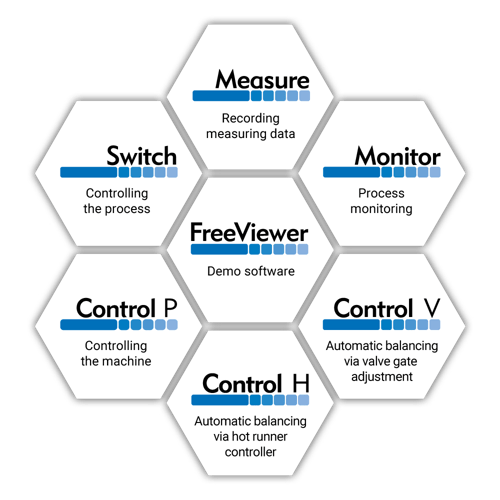

FILLCONTROL is the modular process monitoring system from PRIAMUS that can be flexibly adapted to individual customer requirements. Documenting, monitoring, open-loop or closed-loop process controlling - FILLCONTROL covers all applications with the appropriate module.

Switch Signals when the Melt Front is Detected

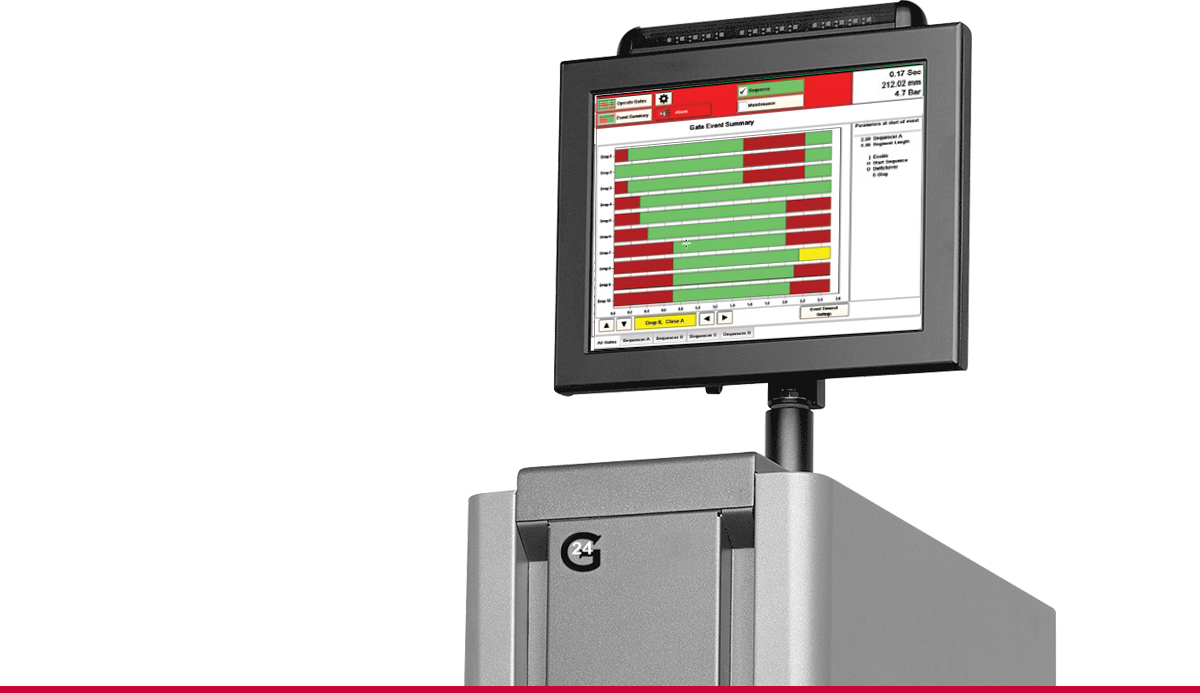

FILLCONTROL Switch generates real-time switching signals on detection of the melt front and thus enables targeted open-loop process control depending on the flow process.

As soon as the melt in the cavity reaches the position of a cavity pressure sensor or a cavity temperature sensor, a switching signal is generated and used for appropriate switching operations depending on the application.

The switching signals can either be delayed or switched on and off depending on each other.

- Automatic Sequential Control

- Valve Gate Nozzle Control

- Core Pull Control

- Automatic Venting

- Rotary Table Applications

- Automatic Injection Compressing Molding

Fill Balancing

FILLCONTROL Control H:

Automatic balancing/ synchronization of filling of all cavities by adjusting hot runner tip temperatures.

In this very effective process, the settings of the hot runner nozzles are permanently corrected depending on the respective melt flow in the cavity. This way, unfilled parts in multi-cavity molds are excluded and weld lines in large-area components are specifically controlled, moved and held in position.

This process is the prerequisite for a systematic reduction of cycle times for multicavity molds.

- Automatic Fill Balancing

- Automatic Melt Flow Control

Control of the Melt Flow

FILLCONTROL Control V balances and controls the melt flow by automatically delaying the opening times of the valve gate nozzles.

Similar to hot runner multi-cavity molds, this leads to all cavities being filled at the same time. This is particularly important for silicone and multi-component applications.

This way, unfilled parts in multi-cavity molds are excluded and weld lines in large-area components are specifically controlled, moved and held in position.

In general, it is possible to regulate the opening times of each valve gate nozzle individually, which, for example, is effectively used for family molds. The nozzles are opened in real time by detecting the melt front in the cavity, so no host computer interface is required.

- Valve Gate Nozzle Balancing

- Valve Gate Nozzle Control